This manual provides essential guidance for installing and operating the Banks iDash 1․8 with aftermarket ECUs‚ ensuring optimal performance and data access․

Banks Power continually updates this manual‚ both in print and online at bankspower․com‚ to reflect iDash 1․8 developments․

Overview of the iDash System

The Banks iDash 1․8 is a versatile super gauge designed for 2008 and newer vehicles equipped with CAN-equipped OBDII systems․ It functions as a comprehensive monitoring and data-logging tool‚ offering real-time performance insights․

This system allows users to choose‚ select‚ and modify gauges displayed‚ customize on-screen safety alerts‚ and log crucial vehicle data – all dynamically․ The iDash 1․8 seamlessly integrates with other Banks products like the Six-Gun Tuner‚ Economind Tuner‚ and SpeedBrake‚ enhancing overall vehicle control and performance monitoring․

Compatible with part numbers 66560‚ 66560-DL‚ and 66561‚ the iDash 1․8 provides a user-friendly interface for accessing and interpreting vehicle information․

Purpose of this Manual

This manual serves as a comprehensive guide to effectively install‚ configure‚ and operate the Banks iDash 1․8 system․ It details the process of connecting the iDash to both vehicle OBDII ports and aftermarket Engine Control Units (ECUs)․

Specifically‚ it provides step-by-step instructions for wiring and configuring ECU communication‚ ensuring seamless data transfer and functionality․ Users will learn how to customize gauges‚ interpret safety alerts‚ and utilize the vehicle data logging capabilities․

Furthermore‚ this resource outlines integration procedures with other Banks performance products‚ maximizing the iDash 1․8’s potential․ Regular updates are available at bankspower․com․

Understanding the iDash 1․8

The iDash 1․8 is a Super Gauge compatible with 2008+ CAN-equipped OBDII vehicles‚ offering on-the-fly customization and data logging capabilities․

Key Features and Capabilities

The Banks iDash 1․8 boasts a comprehensive suite of features designed for performance enthusiasts and professionals alike․ Users can choose‚ select‚ and change gauges within the display‚ tailoring the information presented to their specific needs․

Furthermore‚ the system allows for modification of on-screen safety alerts‚ providing customizable warnings based on critical vehicle parameters․ Vehicle data logging is a core capability‚ enabling detailed analysis of performance metrics․

The iDash 1․8 also excels in interactivity with other Banks devices‚ such as the Six-Gun tuner‚ Economind tuner‚ and SpeedBrake‚ creating a fully integrated performance management system․ This allows for seamless control and monitoring of various vehicle functions․

Compatibility with Vehicles (2008+ CAN-equipped OBDII)

The Banks iDash 1․8 is specifically engineered for use with vehicles manufactured in 2008 and later that are equipped with a CAN-equipped OBDII system․ This compatibility ensures seamless integration and access to a wide range of vehicle data․

The iDash 1․8 effectively interfaces with the vehicle’s onboard computer‚ allowing for real-time monitoring of critical parameters․ It’s important to note that proper connection to the OBDII port is crucial for functionality․

In some vehicle models‚ the OBDII port may require disconnection from its mounting location during installation to facilitate easy access and secure cable connection․

iDash Part Numbers (66560‚ 66560-DL‚ 66561)

Banks iDash 1․8 is available in three distinct part numbers‚ each catering to specific needs and applications․ Part number 66560 represents the standard iDash 1․8 unit‚ offering comprehensive monitoring and control capabilities․

Part number 66560-DL is a specialized version‚ often bundled with additional features or accessories tailored for specific vehicle platforms․ Part number 66561 may represent a variant with unique software or hardware configurations․

This OwnersManual with Installation Instructions is designed for use with all three part numbers‚ providing a universal guide to installation‚ configuration‚ and operation․ Always verify your specific part number before proceeding․

Installation and Wiring

Proper installation involves connecting the Banks OBDII cable to the vehicle’s OBDII port and carefully wiring to aftermarket ECUs for communication․

Connecting the Banks OBDII Cable

To begin installation‚ carefully connect the Banks OBDII cable directly into the vehicle’s OBDII port; It’s crucial to note that‚ depending on the specific vehicle model‚ the OBDII port may require disconnection from its original mounting location to facilitate easier access and a secure connection․

Ensure the connection is firm and fully seated to guarantee reliable data transfer․ This initial step establishes the foundational link between the iDash 1․8 and the vehicle’s onboard diagnostic system‚ enabling access to a wealth of performance data and customizable features․ Always consult vehicle-specific documentation for port location․

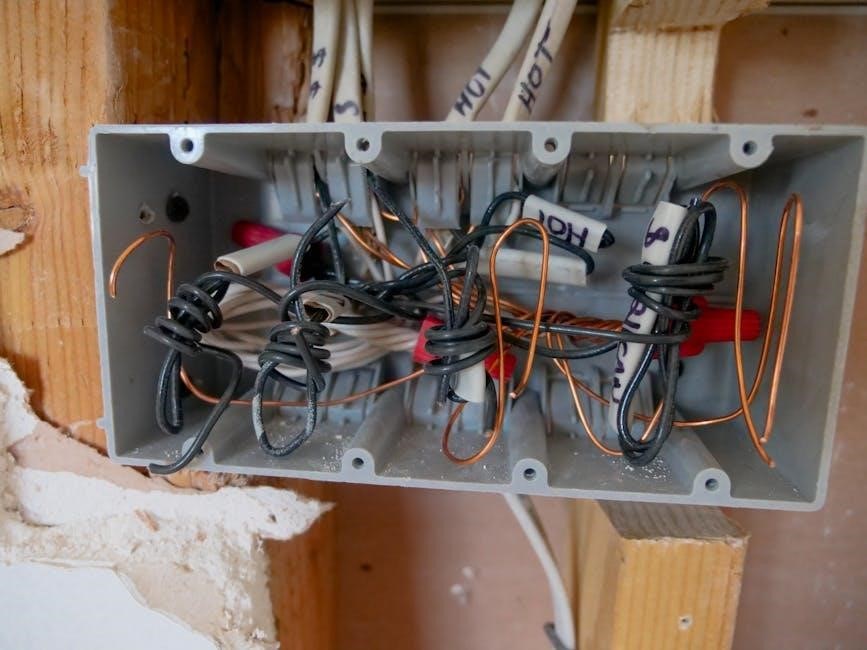

Wiring to Aftermarket ECUs

When integrating the iDash 1․8 with aftermarket Engine Control Units (ECUs)‚ meticulous wiring is paramount․ This process involves establishing a communication pathway between the iDash and the ECU‚ allowing for real-time data exchange and customized parameter monitoring․ Refer to both the iDash 1․8 manual and the specific ECU’s documentation for detailed wiring diagrams and pinout information․

Properly identifying and connecting the necessary wires – typically including ground‚ power‚ and data lines – is critical for successful operation․ Incorrect wiring can lead to inaccurate readings or system malfunction‚ so double-check all connections․

Configuring ECU Communication

After establishing the physical wiring connection to the aftermarket ECU‚ configuring communication protocols is essential; The iDash 1․8 must be programmed to correctly interpret the data stream transmitted by the ECU․ This often involves selecting the appropriate communication protocol (like CAN bus) and defining parameter IDs (PIDs) for specific data points․

Utilize the iDash software interface to configure these settings‚ referencing the ECU’s documentation for accurate PID definitions․ Successful configuration ensures the iDash accurately displays vital engine parameters‚ enabling comprehensive monitoring and performance analysis․

iDash Functionality & Operation

The iDash 1․8 allows on-the-fly customization of gauges‚ safety alerts‚ and vehicle data logging‚ enhancing driver awareness and control during operation․

Gauges and Display Customization

The Banks iDash 1․8 offers extensive customization options for its gauges and display․ Users can choose‚ select‚ and change gauges directly within the display interface‚ tailoring the information presented to their specific needs and preferences․

This flexibility allows drivers to monitor critical vehicle parameters in real-time‚ optimizing performance and ensuring safe operation․ The iDash supports a wide range of gauge configurations‚ accommodating various engine types and aftermarket modifications․

Furthermore‚ the display itself can be adjusted for brightness and contrast‚ ensuring optimal visibility in all lighting conditions․ This level of customization empowers users to create a personalized and informative driving experience․

On-Screen Safety Alerts

The iDash 1․8 is equipped with a sophisticated on-screen safety alert system designed to proactively warn drivers of potential issues․ These alerts are customizable‚ allowing users to define thresholds for critical parameters like engine temperature‚ oil pressure‚ and boost pressure․

When a pre-defined threshold is exceeded‚ a clear and concise alert will appear on the iDash display‚ immediately drawing the driver’s attention․ This feature is crucial for preventing engine damage and ensuring safe operation‚ especially during demanding driving conditions․

Users can also adjust the severity and priority of each alert‚ tailoring the system to their specific needs and driving style․

Vehicle Data Logging

The iDash 1․8 boasts robust vehicle data logging capabilities‚ enabling users to record a wide range of parameters during operation․ This feature is invaluable for performance analysis‚ troubleshooting‚ and monitoring vehicle health․ Logged data includes engine speed‚ coolant temperature‚ boost pressure‚ and numerous other critical metrics․

Data can be reviewed on the iDash display or downloaded to a computer for more in-depth analysis using compatible software․ This allows for detailed examination of driving patterns and identification of potential issues․

The logging frequency is also adjustable‚ providing flexibility to balance data resolution with storage capacity․

Integration with Banks Products

The iDash 1․8 seamlessly integrates with Banks Six-Gun‚ Economind‚ and SpeedBrake systems‚ enhancing functionality and providing a unified monitoring experience․

Banks Six-Gun Tuner Integration

The iDash 1․8 offers comprehensive integration with the Banks Six-Gun tuner‚ providing real-time monitoring of key performance parameters directly on the iDash display․ This allows users to observe the effects of tuning adjustments instantly‚ optimizing engine performance for various driving conditions․

Users can choose‚ select‚ and change gauges within the display‚ customize on-screen safety alerts‚ and log vehicle data – all on-the-fly․ This integration streamlines the tuning process‚ offering a convenient and informative experience for Banks Six-Gun users․ The iDash acts as a powerful visual companion to the Six-Gun’s capabilities․

Economind Tuner Compatibility

The Banks iDash 1․8 seamlessly integrates with the Economind tuner‚ enhancing the user experience with a customizable and informative display․ This compatibility allows drivers to monitor crucial engine data and performance metrics while utilizing the Economind’s fuel efficiency and power-enhancing features․

Users benefit from the ability to select and change gauges‚ adjust on-screen safety alerts‚ and log vehicle data‚ all directly through the iDash interface․ This provides a comprehensive overview of the Economind’s impact on vehicle performance‚ enabling optimized driving strategies and improved fuel economy․

SpeedBrake Integration

The Banks iDash 1․8 offers full integration with the Banks SpeedBrake auxiliary braking system‚ providing drivers with real-time monitoring and control․ This integration displays crucial SpeedBrake data directly on the iDash screen‚ including braking force and system status‚ enhancing safety and confidence‚ especially during towing or downhill driving․

Users can easily monitor the SpeedBrake’s performance and adjust settings through the iDash interface‚ ensuring optimal braking control in various conditions․ This seamless integration allows for a more informed and controlled driving experience‚ maximizing the benefits of the SpeedBrake system․

Advanced Features

The iDash 1․8 allows interaction with other Banks devices‚ software updates via bankspower․com‚ and on-the-fly customization of gauges and alerts․

Interacting with Other Banks Devices

The Banks iDash 1․8 seamlessly integrates with other Banks performance products‚ enhancing overall system functionality․ Specifically‚ it’s designed for compatibility with the Banks Six-Gun tuner‚ the Economind tuner‚ and the SpeedBrake exhaust brake systems․

This integration allows users to monitor and adjust parameters across multiple devices from a single‚ centralized interface․ You can choose‚ select‚ and change gauges within the display‚ modify on-screen safety alerts‚ and log crucial vehicle data – all dynamically and in real-time․ This interconnectedness provides a comprehensive and streamlined user experience․

Software Updates and Online Resources (bankspower․com)

Banks Power is committed to continuous improvement of the iDash 1․8 system․ Regular software updates are released to enhance functionality‚ add new features‚ and ensure optimal performance․ These updates are readily available for download from the official Banks Power website‚ bankspower․com․

The website serves as a comprehensive resource hub‚ offering the latest manuals (in both print and digital formats)‚ frequently asked questions‚ troubleshooting guides‚ and technical support information․ Users are encouraged to visit bankspower․com to stay informed about the newest developments and maximize their iDash 1․8 experience․

Troubleshooting

Common issues‚ like OBDII port access problems‚ are addressed in this section with solutions to help diagnose and resolve iDash 1․8 operational challenges․

Common Issues and Solutions

Experiencing difficulties? This section details frequently encountered problems with the Banks iDash 1․8 and provides practical solutions․ A common issue involves the OBDII port being difficult to access‚ potentially requiring disconnection from its mounting location for proper cable connection․

If the iDash fails to power on‚ verify the power requirements are met and all connections are secure․ For ECU communication errors‚ double-check wiring and configuration settings․ Regularly check bankspower․com for updated software and troubleshooting guides․ Remember to consult the full manual for detailed instructions and diagrams․

OBDII Port Access Issues

Difficulty reaching the OBDII port? Some vehicle models present challenges due to the port’s location and limited accessibility․ In many cases‚ the OBDII port requires disconnection from its original mounting bracket to allow for a secure connection of the Banks OBDII cable․

Carefully disconnect the port‚ ensuring no damage occurs to the wiring or surrounding components․ Re-secure the port after installation if desired․ Always consult your vehicle’s service manual for specific instructions․ If issues persist‚ explore alternative cable extensions or professional installation assistance․

Technical Specifications

The iDash 1․8 boasts specific dimensions and power requirements for optimal integration; detailed specifications are available to ensure proper installation and functionality․

iDash 1․8 Dimensions and Weight

Understanding the physical characteristics of the iDash 1․8 is crucial for successful installation within your vehicle’s dashboard․ While precise measurements aren’t explicitly detailed in the provided snippets‚ knowing the general size allows for proper planning;

The iDash 1․8 is designed as a “Super Gauge‚” implying a compact form factor suitable for replacing or supplementing existing instrumentation․ Consider the available space and mounting options when preparing for installation․

Weight is also a factor‚ though not specified‚ it’s likely minimal to avoid stressing mounting points․ Refer to the complete owner’s manual at bankspower․com for exact dimensions and weight specifications to ensure a secure and aesthetically pleasing fit․

Power Requirements

Ensuring correct power delivery is vital for the iDash 1․8’s functionality and longevity․ While specific voltage and amperage details aren’t directly available in the provided text‚ the iDash 1․8 operates within the standard 12-volt automotive electrical system․

It’s designed for compatibility with 2008+ CAN-equipped OBDII vehicles‚ suggesting it draws power from the vehicle’s existing electrical infrastructure․

Proper wiring and fusing are essential to protect both the iDash 1․8 and the vehicle’s electrical system․ Consult the comprehensive owner’s manual at bankspower․com for detailed wiring diagrams and recommended fuse ratings to guarantee safe and reliable operation․

Safety Precautions

Always disconnect the vehicle’s negative battery terminal before installation․ Proper wiring and fusing are crucial to prevent electrical damage and ensure safe operation․

Important Warnings and Considerations

Exercise extreme caution during installation‚ as improper wiring can lead to vehicle malfunction or damage to the iDash 1․8 system․ Always verify compatibility with your specific vehicle and aftermarket ECU before proceeding․

Ensure all connections are secure and properly insulated to prevent shorts or open circuits․ Avoid running wires near hot engine components or sharp edges․ Regularly inspect wiring for wear and tear‚ replacing damaged components immediately․

Do not attempt to disassemble or modify the iDash 1․8 unit‚ as this will void the warranty and may compromise its functionality․ Consult a qualified technician if you are unsure about any aspect of the installation or operation․

Resources and Support

For assistance‚ explore bankspower․com for software updates‚ FAQs‚ and detailed information․ Additionally‚ Bank of America Private Bank and U․S․ Trust offer support․

Bank of America Private Bank Information (Division of Bank of America‚ N․A․)

Bank of America Private Bank‚ operating as a division of Bank of America‚ N․A․‚ is a Member FDIC and a wholly-owned subsidiary of Bank of America Corporation․ This signifies a commitment to financial stability and client security․ They provide personalized wealth management solutions‚ including investment services‚ estate planning‚ and lending options‚ tailored to high-net-worth individuals and families․

Trust and fiduciary services are specifically provided by Bank of America‚ N․A․‚ and U․S․ Trust Company of Delaware‚ both functioning as indirect subsidiaries of Bank of America Corporation․ This structure ensures comprehensive and regulated financial oversight‚ offering clients peace of mind regarding their assets and financial strategies․

U․S․ Trust Company of Delaware Information

U․S․ Trust Company of Delaware plays a crucial role in delivering specialized trust and fiduciary services․ As an indirect subsidiary of Bank of America Corporation‚ it operates under stringent regulatory standards‚ ensuring the highest levels of client protection and responsible financial management․ These services encompass estate and trust administration‚ investment management‚ and wealth transfer strategies․

The company’s expertise caters to individuals and families seeking sophisticated solutions for preserving and growing their wealth across generations․ U․S․ Trust collaborates closely with Bank of America Private Bank to offer a comprehensive suite of financial services‚ providing a seamless and integrated client experience focused on long-term financial success․